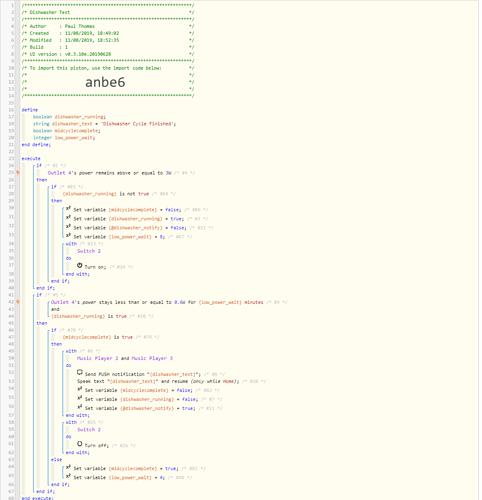

I’m trying to improve my dishwasher complete notification. The current version works well (thanks to WCmore for help on the original)

Basically the code works by waiting until the power has dropped below 0.6w, however this happens mid cycle for 10 mins. So I have to wait 11 mins to trigger the end of cycle. So this means the notification is 11 mins after the cycle completes. I might be being picky, but would like to reduce this time.

A thought I could use a variable on the wait, replacing the 6mins in the code below

![]()

The variable would initially be set to 10 mins, but after the mid cycle activation it would be changed to 2 mins.

The question is would this work? i.e when the piston is rescheduled would the next wait use the current value of the variable.