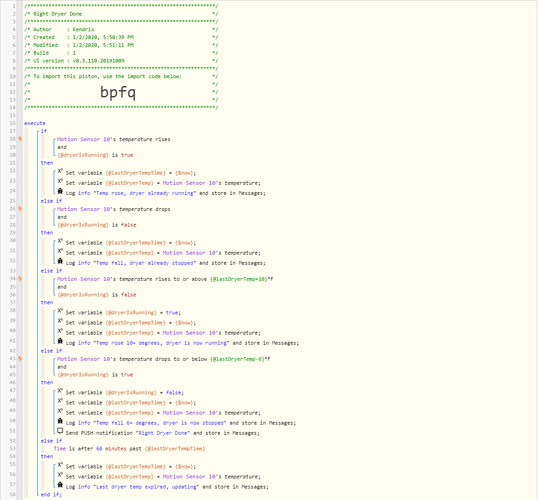

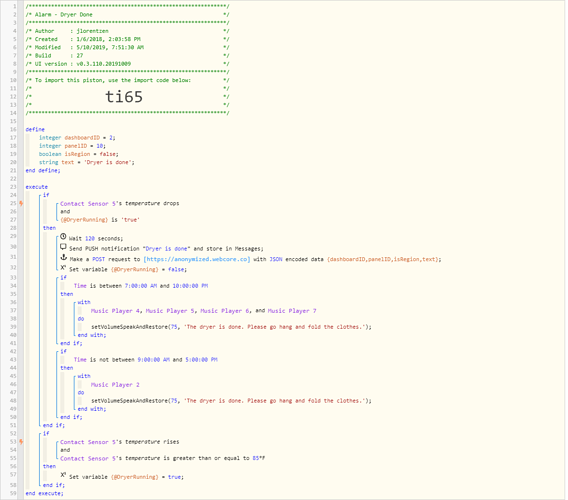

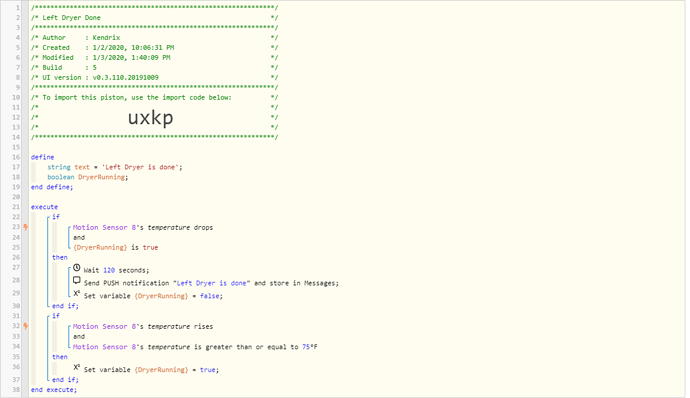

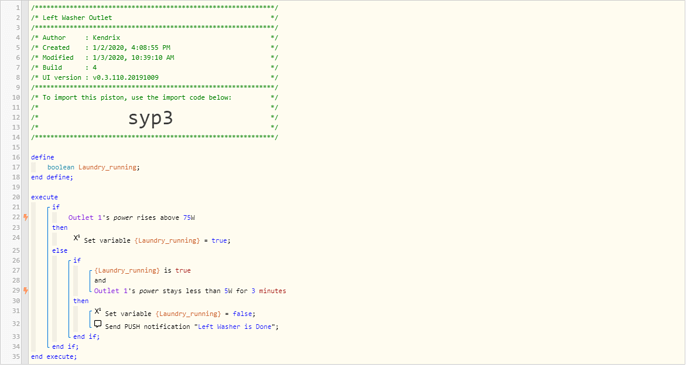

I am seeking assistance with creating a piston in webcore that uses a fabrio sensor for temperature to alert when a dryer is done.

With the sensor I would like it to detect the current temperature, and if the temperature goes up by 10 degrees the dryer is running, should it drop 6+ degrees the dryer has stopped and pushes a notification that the dryer is complete.

I tried using this piston, but I receive this error in the log.

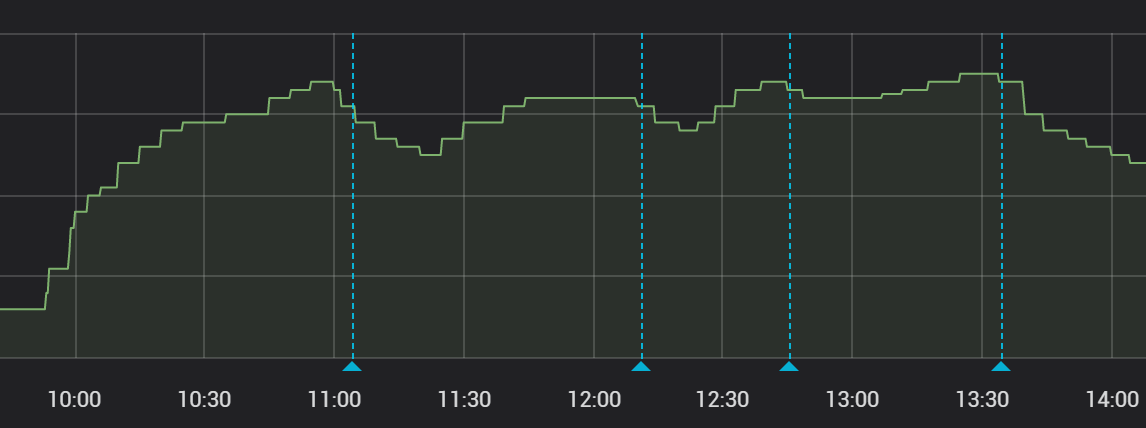

Logs

1/2/2020, 7:04:43 PM +518ms

+96ms ║An error occurred while executing the event: java.lang.NullPointerException: Cannot get property ‘v’ on null object

1/2/2020, 6:49:47 PM +216ms

+77ms ║An error occurred while executing the event: java.lang.NullPointerException: Cannot get property ‘v’ on null object

1/2/2020, 6:34:50 PM +779ms

+110ms ║An error occurred while executing the event: java.lang.NullPointerException: Cannot get property ‘v’ on null object

1/2/2020, 6:19:54 PM +334ms

+111ms ║An error occurred while executing the event: java.lang.NullPointerException: Cannot get property ‘v’ on null object

1/2/2020, 6:04:55 PM +598ms

+101ms ║An error occurred while executing the event: java.lang.NullPointerException: Cannot get property ‘v’ on null object

1/2/2020, 5:51:11 PM +728ms

+508ms ║An error occurred while executing the event: java.lang.NullPointerException: Cannot get property ‘v’ on null object

Any help would be appreciated.