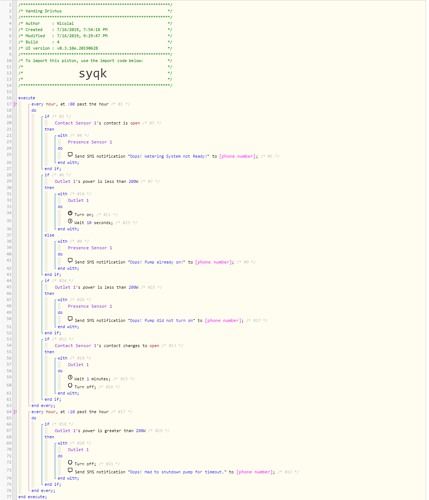

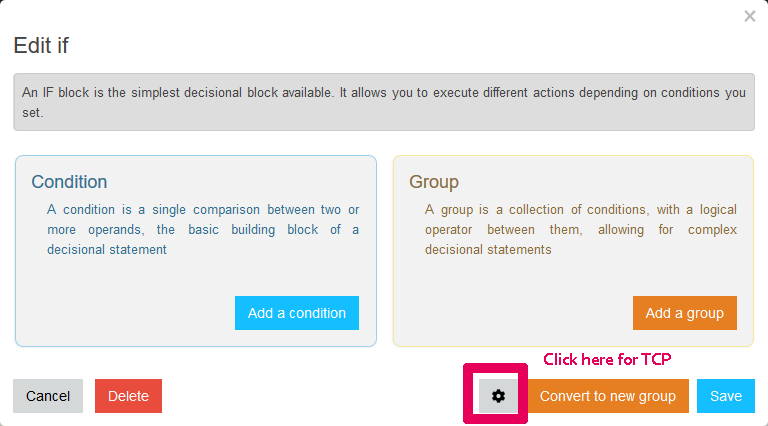

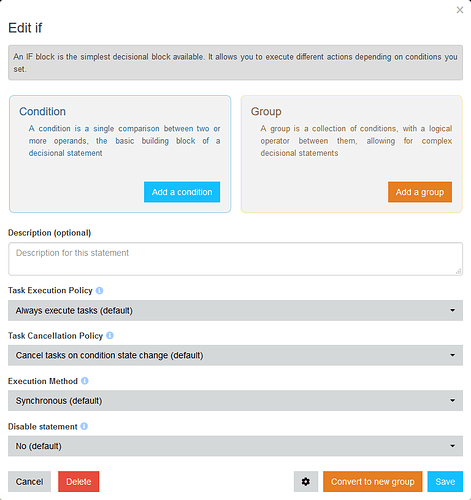

Hi everybody, I am experiencing some trouble figuring out if my pistons are unstable or if I am programming them all wrong.

I’ve. got some basic questions:

Using IF / Else:

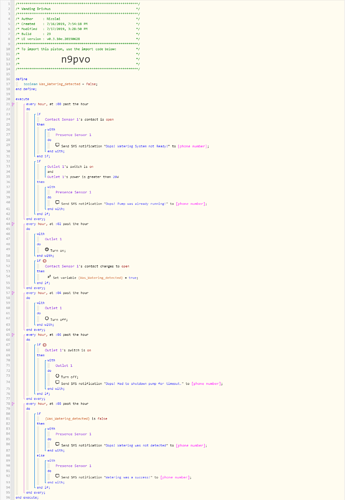

Setup:

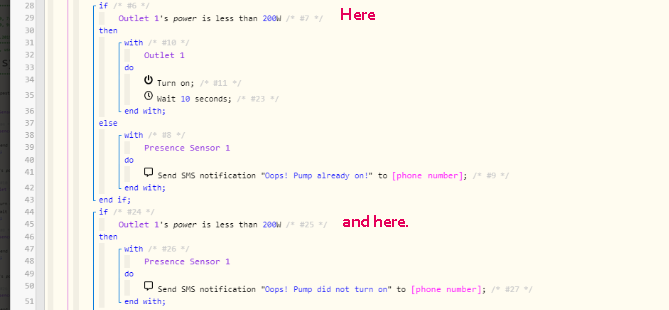

The piston turned on the pump, but I still got a “Oops! Pump already on!”

In my understanding if the first “If” condition is not “met/true” then the “ELSE” statement is run.

If the “IF” statement is “met/True” the “ELSE” statement is NOT run.

How come the pump was turned on and the Sms notification was sent?

Running order:

If a piston contains more than one “IF” statement in what order do they run?

Do the run at the same time or top to bottom or left to right?

Will a wait statement hold all other If statements? If not how do you go about running if’s in a dedicated order?

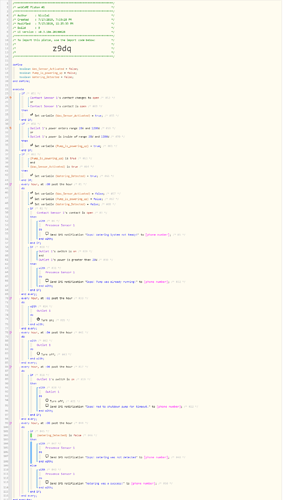

Example:

At 9:00AM every day

DO:

IF Outlet 1 power is less than 100W

Then:

Wait 1 hours

Turn on Outlet 2

IF sensor 1 temperature is more than 25

Then:

Turn on Fan

My question is at what time does the system check the temperature? At 9:00AM or at 10:00AM

Will a wait statement hold all other If statements? If not how do you go about running if’s in a dedicated order?

For instance I would like to turn on a Pump then control if the power output of the outlet rises and notify if the power does not rise (Pump Broken).

Thanks i advance… I’m all new to the Webcore interface so bare with me

Also any link to Documentation / Tutorials beyond the Webcore WIKI would be greatly appreciated.

Nicolai