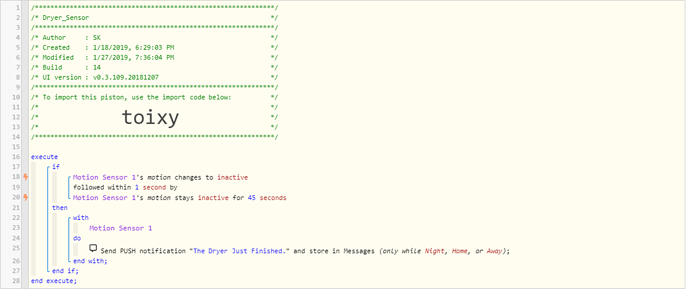

1) Give a description of the problem

I’m using a piston for a motion sensor. When I only use a single argument in the “if” section, the piston performs the action in the “then” section without an issue. If I add an additional argument in the “if” section, it no longer triggers the action in the “then” section. I believe the logic I’m using is correct, but it’s not working for some reason, and I’m unsure why.

2) What is the expected behavior?

I would like to receive a PUSH alert if the motion sensor no longer detects motion for 45 seconds. I would like for the action in the "then" section to execute when I use two arguments in the "if" section.

3) What is happening/not happening?

When I use two arguments in the “if” section, the action in the “then” section doesn’t successfully execute.

4) Post a Green Snapshot of the piston

5) Attach any logs (From ST IDE and by turning logging level to Full)

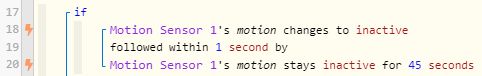

(1/30/2019, 1:13:08 PM +361ms

+2ms ╔Received event [Dryer Sensor].motion = inactive with a delay of 927ms

+10188ms ║RunTime Analysis CS > 21ms > PS > 10121ms > PE > 46ms > CE

+10190ms ║Piston waited at a semaphore for 10058ms

+10192ms ║Runtime (37472 bytes) successfully initialized in 10121ms (v0.3.109.20181207) (10188ms)

+10193ms ║╔Execution stage started

+10204ms ║║Comparison (enum) inactive changes_to (string) inactive = false (1ms)

+10206ms ║║Cancelling condition #2’s schedules…

+10207ms ║║Condition #2 evaluated false (7ms)

+10209ms ║║Cancelling statement #1’s schedules…

+10210ms ║║Condition group #1 evaluated false (state did not change) (11ms)

+10213ms ║╚Execution stage complete. (21ms)

+10215ms ╚Event processed successfully (10215ms)

1/30/2019, 1:13:08 PM +352ms

+2ms ╔Received event [Dryer Sensor].motion = inactive with a delay of 868ms

+122ms ║RunTime Analysis CS > 25ms > PS > 55ms > PE > 41ms > CE

+124ms ║Runtime (37391 bytes) successfully initialized in 55ms (v0.3.109.20181207) (121ms)

+125ms ║╔Execution stage started

+137ms ║║Comparison (enum) inactive changes_to (string) inactive = true (1ms)

+139ms ║║Cancelling condition #2’s schedules…

+140ms ║║Condition #2 evaluated true (7ms)

+141ms ║║Cancelling statement #1’s schedules…

+142ms ║║Condition group #1 made progress up the ladder, currently at step 1 of 2

+149ms ║║Fast executing schedules, waiting for 996ms to sync up

+1154ms ║║Conditional ladder step failed due to a timeout

+1155ms ║║Cancelling statement #1’s schedules…

+1157ms ║║Condition group #1 evaluated false (state did not change) (5ms)

+1159ms ║╚Execution stage complete. (1034ms)

+1160ms ╚Event processed successfully (1160ms)

1/30/2019, 1:12:04 PM +868ms

+1ms ╔Received event [Dryer Sensor].motion = active with a delay of 894ms

+84ms ║RunTime Analysis CS > 23ms > PS > 31ms > PE > 29ms > CE

+86ms ║Runtime (37390 bytes) successfully initialized in 31ms (v0.3.109.20181207) (84ms)

+88ms ║╔Execution stage started

+98ms ║║Comparison (enum) active changes_to (string) inactive = false (1ms)

+100ms ║║Condition #2 evaluated false (5ms)

+101ms ║║Cancelling statement #1’s schedules…

+102ms ║║Condition group #1 evaluated false (state did not change) (9ms)

+104ms ║╚Execution stage complete. (17ms)

+106ms ╚Event processed successfully (106ms)

)