Smart Laundry

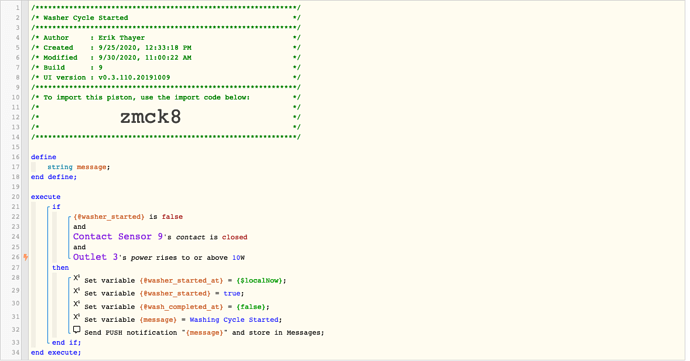

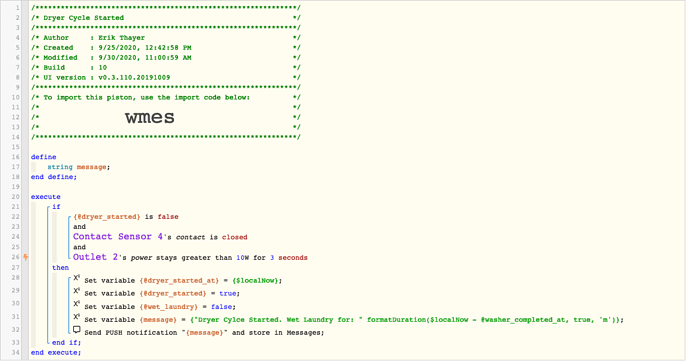

- Requires 2 Energy Monitoring Outlets (Zooz ZEN15 or similar)

- Optional: 2 contact sensors.

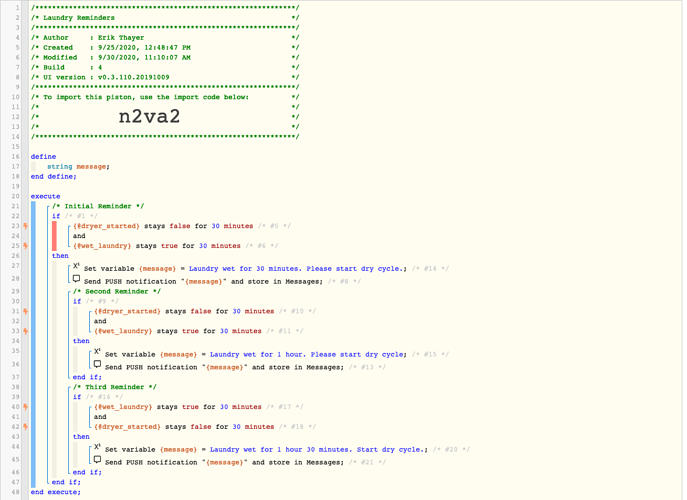

Provides Washer/Dryer alerts and reminders.

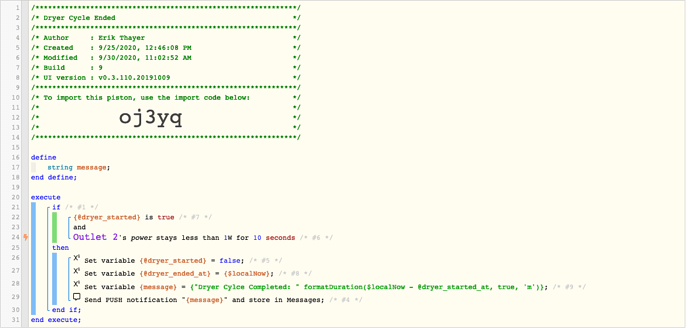

I often forget a wet load of laundry and this is my solution. Seems to work flawlessly with my washer/dryer though the energy-saving timeout on my dryer is about 1minute, so the dryer cycle complete doesn’t trigger for ~1 minutes after the actual end of the cycle.

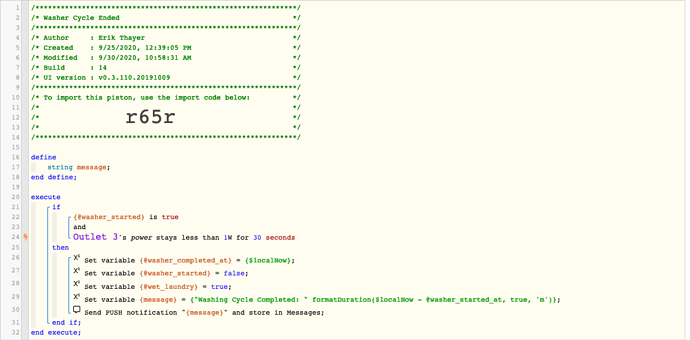

Tells you how long things took and how long it took you to start a dryer cycle after the wash cycle was complete.

This piston would not work well for those who air dry clothes (y’all are A+ citizens). An escape loop for air-dry cycle would need to be made, either with a button press or using the contact sensor for opening the washing machine.

Messages are stored in a variable before the push notifications are made. This is so that a user could add an additional SMS notification if desired and use the same {message} variable.

Global variables are used so that other pistons in my house can use their data (such as my house ‘go to bed’ piston warning me if I go to bed with a pending laundry load)

Global Variables:

boolean: @dryer_started

datetime: @dryer_started_at

datetime: @dryer_completed_at

boolean: @washer_started

datetime: @washer_started_at

datetime: @washer_completed_at

boolean: @wet_laundry