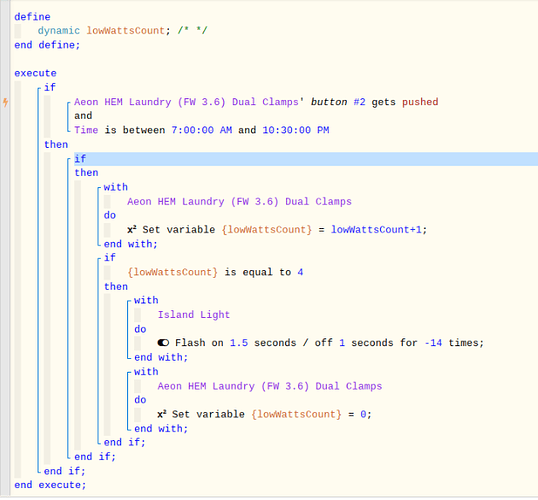

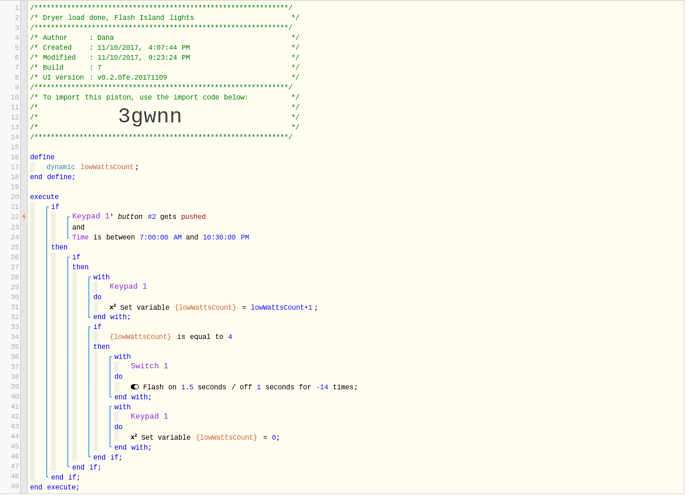

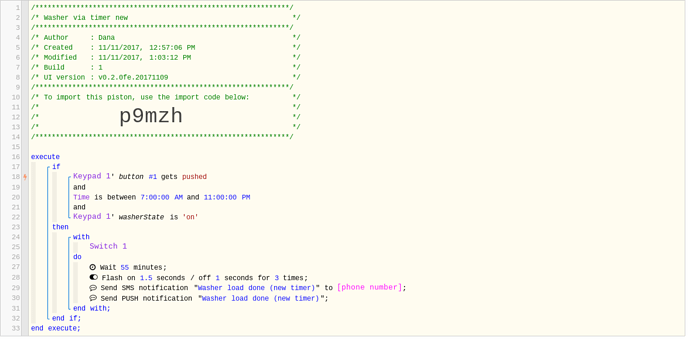

I"m using an Aeon dual clamp HEM to monitor power on a washer (clamp 1) and dryer (clamp 2) using a custom DTH that assigns a button push when the energy consumption hits a certain number of watts consumed. There are two virtual buttons (Button1 and Button2), one for each clamp.

I use this to monitor when the washer and dryer are done via watt consumption, and notify by flashing lights, etc. The washer is easy, as it drops to a low number of watts at the end of the cycle and stays there. My old dryer was the same.

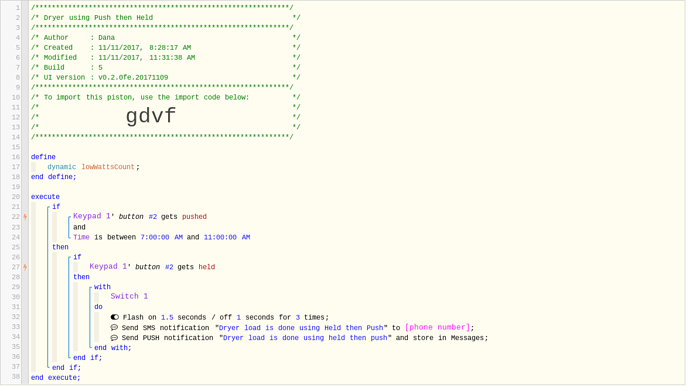

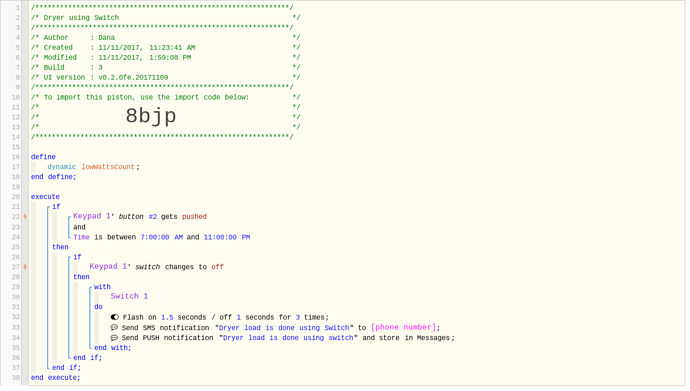

However, I got a new dryer recently, and this dryer doesn’t have the same simple power consumption pattern. At the end of the cycle it drops to 8 watts four times, and then goes into wrinkle prevent mode (which can also drop to 8 watts). I want to use the repeatable event (four times at 8 watts) to mark the end of the cycle.

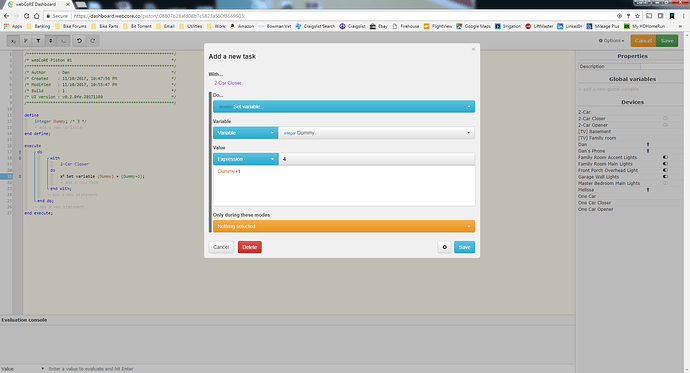

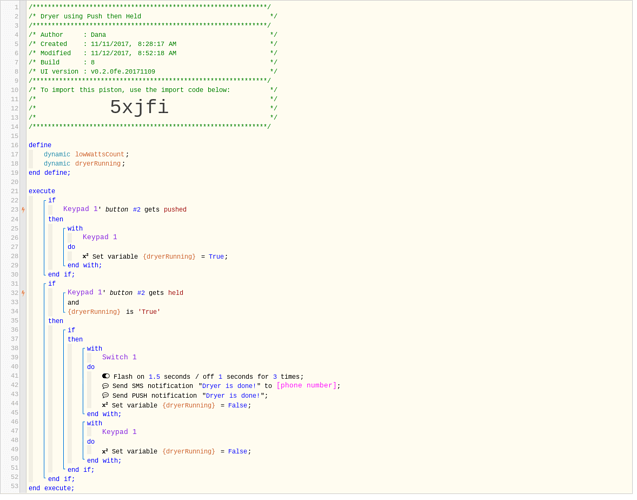

I have set my dryer clamp virtual button trigger to press at 8 watts, and need to count those four virtual button presses, and at the fourth, trigger my “dryer is done!” notifications.

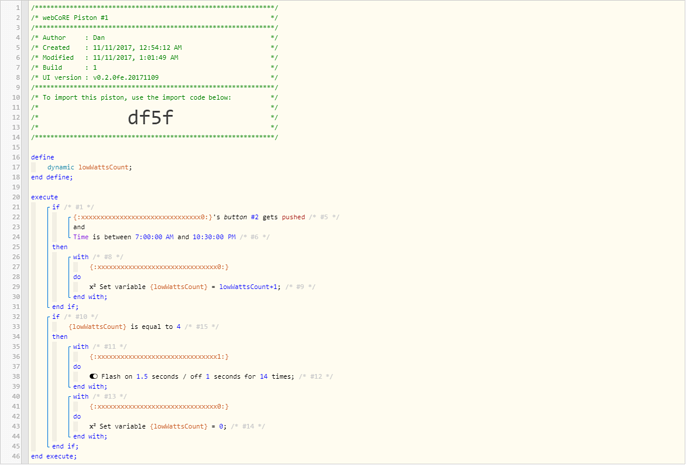

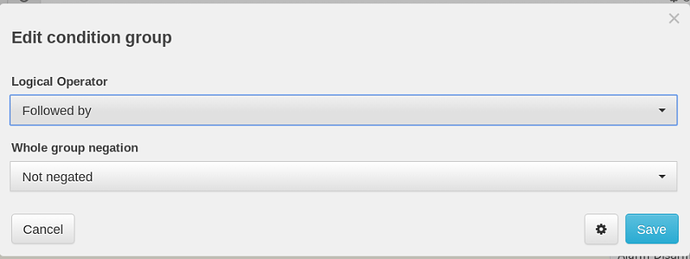

I don’t see any example pistons in the wiki that have this capability to build off of. I know that part of the solution is creating a number variable and incrementing it up to 4, sending notifications, and then resetting the button to zero, but I couldn’t find help in the wiki on this.

Does anyone have a piston like this they can share, or can you help me w/some direction/pointers? Thanks!